Tilting assamblage table machine for pressing of aluminium profiles into window and door glasses with Baertec quality.

You want to press sliding aluminium profiles into glasses with an semi automatic machine? Here we can offer your company our assambly tiliting table 3000 for fixing /pressing the glasses in the inside of the sliding aluminium profiles with Baertec quality for a price-performance ratio which is incredible 8.900,00 Euro. If you want to see this or other machines in action please visit our official website www.baertec.com This machine is designed and manufactured specially for aluminium profiles and glasses. After the full welding process of the table we put the machine table body in a hot ofen (5 metres x 5 metres) with 800 degree temperature for two days, to take the welding stress out of the steel profiles.

Heat treating is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve a desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, normalizing and quenching. It is noteworthy that while the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding. Metallic materials consist of a microstructure of small crystals called “grains” or crystallites. The nature of the grains (i.e. grain size and composition) is one of the most effective factors that can determine the overall mechanical behavior of the metal. Heat treatment provides an efficient way to manipulate the properties of the metal by controlling the rate of diffusion and the rate of cooling within the microstructure. Heat treating is often used to alter the mechanical properties of a metallic alloy, manipulating properties such as the hardness, strength, toughness, ductility and elasticity.

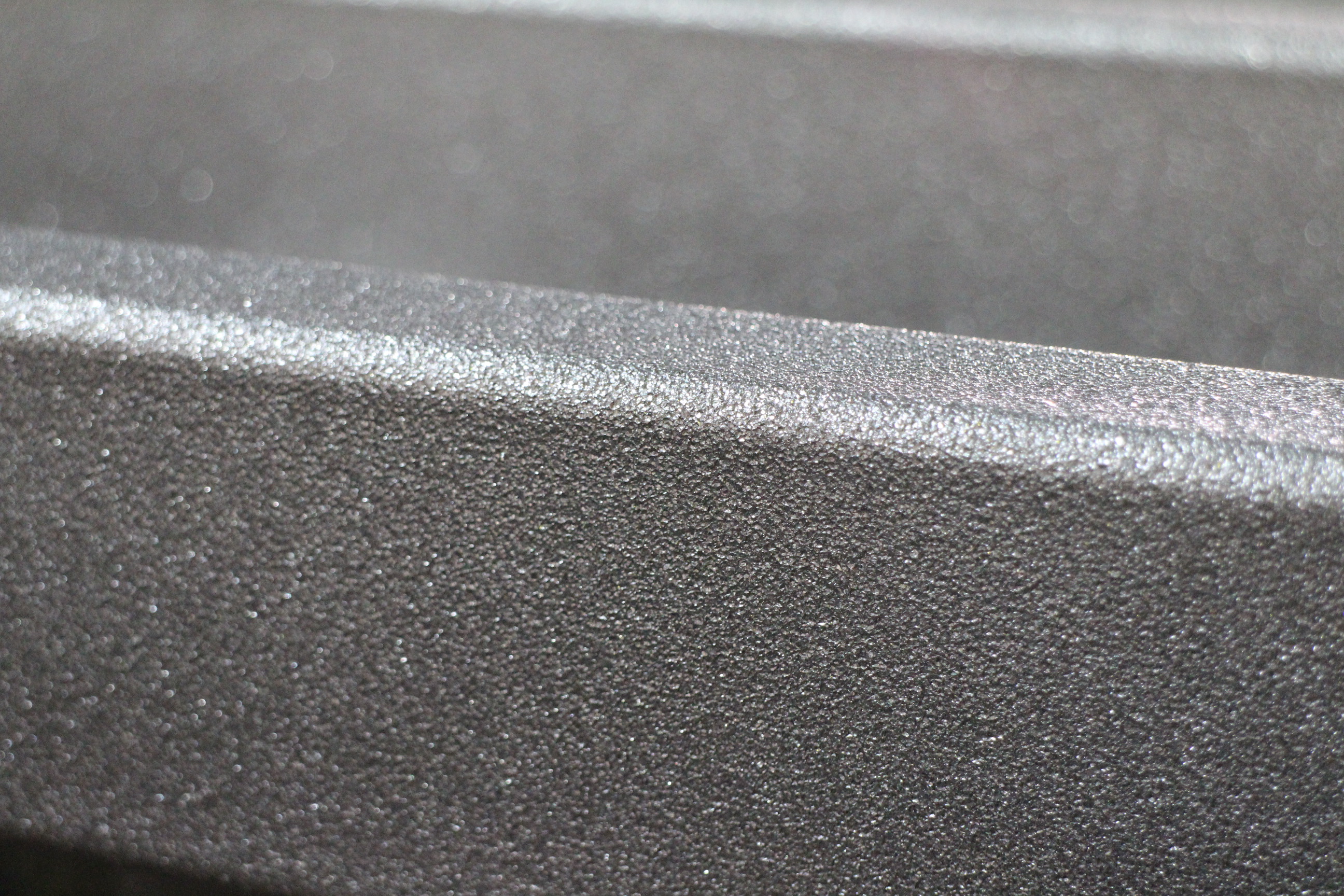

The second step is the sand blasting room where the welded table goes through the abrasive blasting process.

The third step is the press machine to restore bended steel profiles which is a result of the first step welding process. The last resort before the table goes to our montage hall is the surface cleaning process. Please check the video.

What can happening if you are not buying from Baertec? Your machine from different competition companies can bend every year some mm like a Banana, the reason for that is the welding stress in the inside of the machine body, at last the machine can stop to work. Your investment is collected from the garbage collection.